Abstract submission is now open

We would like to offer the opportunity to submit papers for this conference in the general field of characterisation. This meeting will showcase the growing number of examples where the range of currently available characterisation techniques has demonstrated the controlling structural features in complex formulations. Authors of successful abstracts will be offered the opportunity to present an oral paper on the topic. There will also be ample opportunities to present work in the form of posters.

Abstracts should consist of a one- paragraph summary (ca 150 – 200 words) and the contact details of the authors and a contact address.

Submission

Please use the abstract template [download document]

Once complete this should be sent as a word document to the conference secretariat Constable & Smith Events by E Mail at

Understanding microcapsule properties for developing consumer products

Zhibing Zhang, School of Chemical Engineering, University of Birmingham, Birmingham B15 2TT, UK

Email:

Microcapsules for consumer products should have desirable physicochemical, structural and mechanical properties. One example is microcapsules containing liquid perfume used in detergents. The shell of the microcapsules should ideally be non-permeable, they should adhere to fabric surfaces in washing machine and can be ruptured by mechanical forces generated at end use, i.e. friction and rubbing between human body and fabric fibers. For such application, it is crucial to optimize the mechanical strength of microcapsules in addition to reducing perfume leakage in detergents during storage and enhancing their adhesion on fabric surfaces.

The mechanical properties of microcapsules can be measured by a micromanipulation technique, which generates the data of the force required to cause a given deformation of single microcapsules, diameter, visco-elastic-plastic behaviour, rupture force and displacement at rupture (1). The intrinsic material property parameters, such as Young’s modulus, yield stress, plastic modulus, and stress/strain at rupture can be determined by numerical modelling of the force versus deformation data with appropriate constitutive equations of the shell materials based on finite element analysis (2). Microcapsules with a shell of melamine formaldehyde and a core of oil-based perfume have been extensively investigated using the technique. The adhesion of single microcapsules on flat fabric surfaces was measured using atomic force microscopy (3). The rate of perfume release from microcapsules to aqueous environment was quantified based on an accelerated experiment by adding a water-soluble organic solvent to the aqueous environment, which dramatically increased the solubility of perfume in the liquid but did not interact with the polymer shell significantly (4). The data of the mechanical strength, adhesion on fabric surface, perfume leakage rate of microcapsules combined with their size, chemical composition, and structure can be used to optimise their formulation and processing conditions, leading to commercialization of perfume microcapsules in detergents. The details of these studies will be presented.

References:

1. Sun, G. and Zhang, Z. (2001) J Microencapsulation. 18: 593-602.

2. Mercadé-Prieto, R., Allen, R, York, D., Preece, J. A., Goodwin, T. E. and Zhang, Z. (2012) AIChEJ 58: 2674–2681.

3. He, Y., Bowen, J., Andrews, J. W., Liu, M., Smets, J. and Zhang, Z. (2014) J Microencapsulation 31: 430-439.

4. Mercadé-Prieto, R., Allen, R, York, D., Preece, J. A., Goodwin, T. E. and Zhang, Z. (2012) J Microencapsulation 29: 463-474.

Correlative Tomography: 3D characterization across time and length scales

T L Burnett, P J Withers, School of Materials, The University of Manchester, Manchester, M13 9PL, UK

There are a huge array of characterization techniques available today and increasingly powerful computing resources allowing for effective analysis and modelling of large datasets. However a majority of these experimental and theoretical tools span only very limited time and length scales.

Correlative tomography can be thought of as the extension of correlative microscopy (e.g. the use of optical fluorescence microscopy to identify a region of interest followed by high resolution electron microscopy of the chosen region) into three dimensions. By establishing rigorous ways of connecting different techniques operating at different scales it is possible to cover a large range of scales not restricted by one particular technique.

For example we have monitored a corrosion process take place using time lapse X-ray computed tomography (CT) (also known as 4D imaging), this would typically be recorded at a certain specific resolution, allowing visualization of the corrosive attack over an entire component. After monitoring the corrosion it was possible to zoom in and image one specific region of corrosive attack using high resolution X-ray CT. From this high resolution 3D X-ray CT dataset it was then possible to prepare a region for serial sectioning electron tomography using the focussed ion beam (FIB)-scanning electron microscope (SEM). Correlative tomography provided a new level of detail by delivering a multiscale 3D picture of the degradation [1].

In this paper we present the application of correlative tomography to several different case studies with a focus on the combination of X-ray CT and serial sectioning electron tomography.

References

[1] Burnett et al, Correlative Tomography, Scientific Reports 4, Article number: 4711 (2014) doi:10.1038/srep04711

Nanoparticle tracking analysis as a technique for sizing and diffusion studies

Vitaliy Khutoryanskiy, Reading School of Pharmacy, University of Reading, Whiteknights PO Box 224, Reading RG66AD, UK

Nanoparticle tracking analysis (NTA) is a physical technique that can be used to characterise the dimensions of nanomaterials in liquid media (Newtonian fluids). The technique allows tracking the Brownian motion of individual nanoparticles and through the analysis of their diffusion characteristics using the Stokes−Einstein equation it provides data on the particle size and size distributions. We have used this technique to study the diffusion of silica nanoparticles functionalised with different polymers in aqueous solutions of water-soluble polymers [1] and in dispersions of porcine gastric mucin [2].

Thiolated silica nanoparticles were synthesised using self-condensation of 3-mercaptopropyltrimethoxysilane in dimethylsulphoxide as described previously [3]. These nanoparticles were decorated with 5 kDa polyethyleneglycol and poly(2-ethyl-2-oxazoline), and were additionally fluorescently labelled.

The diffusion of these nanoparticles in aqueous polymer solutions was studied using NTA. It was established that the diffusivity of nanoparticles is affected by their dimensions, medium viscosity, and the specific interactions between nanoparticles and the macromolecules in solution. Strong attractive interactions such as hydrogen bonding were found to hamper diffusion [1].

The NTA study of diffusion in aqueous mucin dispersions demonstrated that decoration of nanoparticles surface with poly(2-ethyl-2-oxazoline) or poly(ethylene glycol) enhances their ability to travel through mucus. The diffusion results generated by NTA were in good agreement with the data on the permeation of these nanoparticles through ex vivo porcine stomach mucus.

References

1. Mun E.A., Hannell C., Rogers S.E., Hole P., Williams A.C., Khutoryanskiy V.V. On the role of specific interactions in the diffusion of nanoparticles in aqueous polymer solutions, Langmuir, 30, 308-317 (2014)

2. Mansfield E.D.H., Sillence K., Hole P., Williams A.C., Khutoryanskiy V.V. POZylation; a new approach to enhance nanoparticle diffusion through mucosal barriers, Nanoscale, 7, 13671-13679 (2015)

3. Irmukhametova G.S., Mun G.A., Khutoryanskiy V.V. Thiolated mucoadhesive and PEGylated non-mucoadhesive organosilica nanoparticles from 3-mercaptopropyl-trimethoxysilane, Langmuir, 27, 9551-9556 (2011)

New solid-state NMR methods for characterisation of controlled release formulations

Staffan Schantz1, Judith Schlagnitweit2,3, Mingxue Tang2,4, Maria Baias2,5, Aaron J. Rossini2,6, Anna Svensk Ankarberg1, Sara Richardson1, Lyndon Emsley2,7

1AstraZeneca R&D, Pharmaceutical Development, Mölndal, Sweden

2Centre de RMN à très hauts champs, Université de Lyon (ENS Lyon/CNRS/UCB Lyon1), France

3Current address: GSK Medicines Research Centre, Gunnels Wood Road, Stevenage, UK

4Current address: CNRS, Université d’Orleans, F-45071 Orléans Cedex 2, France

5Current address: New York University Abu Dhabi, PO Box 129188, Abu Dhabi, United Arab Emirates

6Current address: Iowa State University, Department of Chemistry, Ames, IA, USA

7Institut des Sciences et Ingénierie Chimiques, EPFL, CH-1015 Lausanne, Switzerland

Contact email:

We have developed a series of new solid-state NMR methods suitable for coated pellet formulations to determine domain sizes selectively of hydroxypropyl cellulose (HPC) and ethyl cellulose (EC),1-2 respectively, common cellulose derivatives used in pharmaceutical formulations. The methods have been applied directly to controlled release samples from industrial coating processes to guide formulation development.

As a brief background, controlled release formulations almost always include polymers, for example as films applied in spray coating processes onto active drug particles. To tailor-make the formulation in terms of its drug release time profile, it is convenient to use hydrophilic/hydrophobic polymer mixtures such as HPC/EC which form single-phase systems in dilute solution but phase separate during film formation as the solution is rapidly concentrated. In the solid dosage form, the hydrophilic coating component may provide pathways for water to dissolve the drug core, thus emphasizing the key role of the coating phase structure. Especially for film coatings in controlled drug delivery, to better understand and control the in-vivo plasma concentration of a drug over time, it is crucial to determine the structure and the domain size of each coating component. So far however, structure-property relations of such multi-phase blends have provided major challenges mainly because of the complex phase structure formed in the kinetic drying process but also because the presence of many other formulation components typically gives severe spectral overlap in most analytical techniques.

References

[1] J. Schlagnitweit, M. Tang, M. Baias, S. Richardson, S. Schantz, L. Emsley,

J. Magn. Reson., 261 (2015) 43-48.

[2] J. Schlagnitweit, M. Tang, M. Baias, S. Richardson, S. Schantz, L. Emsley,

J. Am. Chem. Soc., 137 (2015) 12482-12485.

Small-Angle Neutron Scattering: Applications to Multi-Component Systems

Sarah E. Rogers

ISIS, STFC. Rutherford Appleton Laboratory, Harwell Campus, Didcot. OX11 0QX. UK.

Small-Angle Neutron Scattering (SANS) is a powerful technique for determining microstructure in the dimension range of tens to thousands of Angstroms. SANS has become invaluable to many scientists in the soft matter community as a method of obtaining information such as size, shape and polydispersity in a variety of multi-component systems such as commonly studied by formulation scientists.

Neutrons have specific advantages over other forms of radiation (X-rays and light) such as they have a high penetrating power, they are non-destructive, they have a magnetic moment and they scatter from materials by interacting with the nucleus of an atom. The final point is one of the most significant features of neutron scattering when studying multi-component systems. The neutron scattering power of atoms varies, randomly, from element to element and isotope to isotope. This means that light atoms, such as hydrogen, can be distinguished from heavier atoms, such as metals. Also, importantly, this dependence allows isotopes of the same element to have substantially different scattering powers and so by altering the isotopic content of a sample (switching the solvent from H2O to D2O, for example) or by using isotopic substitution with a molecule (D for H, for example) specific areas of interest within the system under investigation can have their scattering power enhanced without appreciably changing the chemical properties of the sample.

At ISIS there are two operational SANS beamlines, Loq and Sans2d, a third currently being commissioned, Larmor, and a fourth, Zoom, is under construction. The complementary design of these beamlines and the extensive range of sample environment available allows a very broad range of lengthscales and science to be studied via SANS at ISIS.

In this talk the general principles of SANS will be discussed along with possible applications to formulation science.

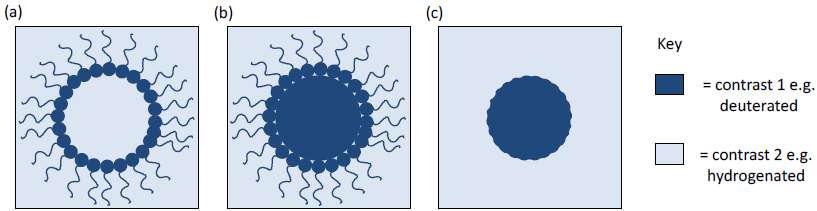

Figure: Schematic representation of how selective deuteration can give direct structural information on (a) the surfactant shell layer, (b) the entire drop and (c) the core structure of an idealised surfactant stabilised system.

(a)(b)(c)Key= contrast 1 e.g. deuterated= contrast 2 e.g. hydrogenated

Clever Characterisation a Different Approach – HTE

Dr Simon R Gibbon

AkzoNobel RD&I, PO Box 221, Northallerton, North Yorkshire, DL7 7BJ, UK

Historically, the greatest publicity for high throughput experimentation (HTE) has been in the biochemical sciences which rapidly adopted HTE due to a combination of the development of automated analysis equipment and rapid screens which are able to identify chemicals / biological molecules with a given trait. The availability of large libraries of candidate materials allows HTE methods to be applied whenever a new trait is required.

The situation is rather different for formulated products, where “traits” of interest are often not easily measured and new formulations are not simply available from libraries. In 2004 the InsightFaraday partnership funded by what is now InnovateUK produced “A Roadmap for High Throughput Technologies” which includes a nice summary of some of the challenges formulation present for HTE (1).

The other challenge is that unlike simple chemicals, formulated products contain multiple ingredients and their method of production has a big effect on their end properties. Formulated products suffer from a scale-down effect, where a “simple” mixing process at 1g, 10g, 1Kg and 1Tonne scale will produce products with different structures and hence properties. NIST addressed many these issues during a 10 year multi-industry study (2).

In fact some formulation properties are can be rapidly measured, such as for a paint its colour (3) or in the case of a detergent its cleaning ability. However, in many areas of formulation such rapid screens are not available to measure the properties of importance for the end application. Many other properties of formulations whether ease of application, taste, feel, texture or even smell, cannot be rapidly measured.

However, considerable success in high throughput approaches to formulated product optimisation has been achieved by the use of clever characterization to ensure that property measurement at different scales can be compared. The European Centres at Liverpool and Flamac are both applying high throughput technologies to formulation for a range of industries (4).

This talk will present an approach to formulation which builds on the ability to rapidly acquire a range of relevant data from simple measurements that are able to be used to reduce the formulation space to a size which can be optimised by more normal methods.

References

[1] Insight Faraday Partnership, “A Roadmap for High Throughput Technologies”, 2004, p22, http://bit.ly/1US8dV7

[2] EJ Amis, “Combinatorial materials science: Reaching beyond discovery”, Nature Materials, 2004, 3, p83-85

[3] FA Alamer, MT Otley, Y Ding, GA Sotzing, “Solid-state high-throughput screeing for color tuning of electrochromic polymers”, Advanced Materials, 2013, DOI: 10.1002/adma.201302729

[4] https://www.liverpool.ac.uk/materials-discovery/ http://www.flamac.be/