Abstracts

Abstract submission is now open

We would now like to offer an opportunity to submit papers for this conference in the general field of functional films and coatings. Areas to be considered include novel routes to their manufacture, the properties that such products exhibit, whether in the area of thin films or coatings based on multicomponent formulations. Other topics could include the analysis of such material. The application areas can be anything from pharmaceutical, cosmetics, agrochemicals, veterinary, to smart materials such as inks and adhesives.

Authors of successful abstracts will be offered the opportunity to present a poster on the topic. There will also be ample opportunities to present work in the form of posters which will be promoted in the form of a flash poster presentation early in the day.

Abstracts should consist of a one- paragraph summary (ca 150 – 200 words) and the contact details of the authors and a contact address.

Abstract Template - abstract template.doc.

Once complete this should be sent as a word document to the conference secretariat

N.B. We are able to offer a limited number of free student places to students who submitted an abstract which is accepted.

Advances in Passive and Active Coatings Technology for Glass: Insight into the evolving role of coatings and related technology in the flat glass industry

Rory Back

Incubation & Value-Added-Product Technical Manager for NSG Pilkington in the UK.

Previously, the improvement of aesthetics and thermal performance of glazing has been focussed on the introduction and subsequent enhancement of Solar Control and Low Emissivity coatings. Opportunities are present for the glass industry to develop both advanced passive and active/dynamic technology for façades. Such a challenge demands new skillsets and innovative thinking, which can be hard to foster within one working environment alone. Established flat-glass producers and innovative start-ups can combine knowledge, expertise, and resources. This talk presents new developments in both passive and active glass technology, including bird-safe glazing, photovoltaic technology, dynamic windows, and the digitisation of the analogue glass building material. It also shares a vision and best practice examples of how a multinational glass manufacturer and an Industry 4.0 start-up can join forces to innovate beyond their separate capabilities.

Formulation and analysis of barrier materials in flexible electronic devices

Paolo Melgari

Principal Scientist, CPI, Sedgefield, County Durham

The use of air- and moisture-sensitive materials in the electronics industry has driven the development of commercially-viable barrier technology. CPI has addressed this challenge by employing Atomic Layer Deposition (ALD) to apply barrier materials as nano-scale thin films onto a plastic film, which is then protected with a polymeric formulation. Further development has allowed the direct deposition of the barrier onto electronic devices (no carrier film required) and 3D SIMS mapping has been used to optimise the full electronic materials stack. The development of ALD technology has permitted the usage of the formulated thin films for an ion selective/permeable barrier in battery applications and their first use for Electric Vehicle batteries is reported.

Nanoencapsulaion for Heat Storage

Dmitry G. Shchukin

Stephenson Institute for Renewable Energy, University of Liverpool, L69 7ZF Liverpool, UK

Thermal energy storage in low temperature region is most efficiently achieved using phase change materials. Crystallohydrates have advantages over organic PCMs such as high energy storage density, high latent heat and incombustibility. However, they suffer from drawbacks such as incongruent melting and corrosion of container materials.

Presented work describes new and universal nanoencapsulation approach for protection and increased performance of the inorganic crystallohydrate phase change materials (PCMs). Comparing to the organic PCMs, inorganic PCMs have never been successfully encapsulated before into the nanosized capsules and halloysites. Here, we demonstrate a simple method to nanoencapsulate crystallohydrates by in situ miniemulsion polymerisation using sonication as well as encapsulation into halloysite nanotubes. Results show the capsules are 100-200 nm and stable over at least 500 thermal cycles. Supercooling is also drastically reduced.

Nanoencapsulation can increase the efficiency of inorganic PCM materials. The high specific surface area, prevented exchange of encapsulated material with environment, controlled heat exchange across the capsule shell and congruent melting/crystallisation due to the small core size are beneficial for future PCM materials based on nanoencapsulation. Energy nanocapsules can find new application fields in thermal energy storage like cascade multitemperature energy systems, additives to thermal paints or textiles, etc.

Solutions for Smart Sensor Applications

Dr. Marisa Phelan

Rapid Systems Platform, Henkel Ireland Operations and Research Ltd

Functional inks and printed electronics solutions are offered by Henkel to enable the production of smart sensors in an easy and economically attractive way. These sensors can be integrated into existing products in many different applications ranging from healthcare, automotive to industry 4.0. The integration can be realized in an uncomplicated way that enables monitoring desired functions, such as moisture, heat, pressure, bio signals in an unobtrusive and cost effective manner.

Cellulose-based Photonic Films

Richard M. Parker, Tianheng Zhao, Bruno Frka-Petesic, Silvia Vignolini

University of Cambridge

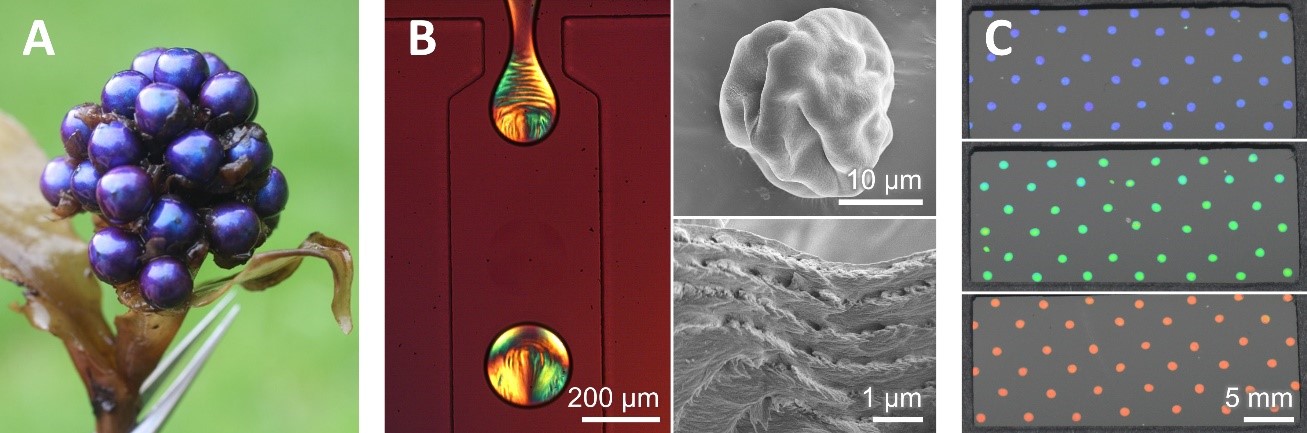

By controlling the interaction between elementary building blocks, nature is able to optimize a large variety of materials with multiple functionalities, giving rise to e.g. enhanced mechanical or optical properties. Such control is however extremely challenging in man-made materials, due to the difficulties in simultaneously manipulating their interactions across different length‑scales. Inspired by the helicoidal architectures found in the plant cell wall, we will discuss the self‑assembly of cellulose nanocrystals into hierarchical cholesteric architectures to produce vibrantly coloured films and coatings.

Cellulose nanocrystals (CNCs) are bio-sourced chiral nanorods that are known to spontaneously self‑organise in water into a cholesteric liquid crystalline phase. Upon evaporation, this helicoidal arrangement can be retained in the solid-state in order to produce films that strongly reflect visible light.[1] While the strong chiroptical properties and non-fading character of bio-compatible CNC films has generated considerable interest within the cosmetics, food and security industries; a scalable self‑assembly route or a method to produce a dispersible photonic pigment has limited their commercial uptake. In this talk we will highlight our recent strategies to produce scalable CNC films and coatings, by exploiting the confinement effects found within micron-sized aqueous droplets.[2,3]

(A) Structurally coloured fruits of Pollia condensata (image from Paula Rudall). (B) Photonic microparticles made from cellulose nanocrystals. [3] (C) Red, green and blue cellulose nanocrystal microfilms.[2]

[1] R. M. Parker, G. Guidetti, C. A. Williams, T. Zhao, A. Narkevicius, S. Vignolini, B. Frka-Petesic, Adv. Mater. 30, 1704477.

[2] T. H. Zhao, R. M. Parker, C. A. Williams, K. T. P. Lim, B. Frka-Petesic, S. Vignolini, Adv. Funct. Mater. 2019, 29, 1804531.

[3] R. M. Parker, B. Frka-Petesic, G. Guidetti, G. Kamita, G. Consani, C. Abell, S. Vignolini, ACS Nano 2016, 10, 8443.

Safety of food packaging: migration tests on printing inks

Marina Santos

Domino Printing Sciences

Migration is the transfer of substances from the packaging to the food and is a main concern for the food packaging supply chain. With inks used for food packaging applications, there is a risk of chemicals being transferred to food.

Not all the primary materials of our inks and cartridges are fully characterized. Moreover, printing inks can contain non-intentionally added substances (NIAS) such as impurities, reaction intermediates and breakdown products from different sources or as a result of processes used during the packaging production. When investigating NIAS, the analysis is challenging because typically there is very little information of the potential chemicals involved. Therefore, the approach taken needs to be as non-selective as possible and sensitive enough to avoid extensive sample preparation and pre-treatment.

This talk presents our efforts to understand the migration behaviour of our inks while ensuring migration does not occur above defined acceptable limits, and focuses on the utilization of GC-MS and LC-MS for the confident identification of migrants in food simulants at ultra-trace levels.

Improving the environmental credentials of inkjet inks: using lifecycle assessment as an innovation tool

Dr Josie Harries

Domino Printing Sciences

With consumers and businesses now being more aware of the impact that their activities may have on the environment, many organisations have identified improving the environmental credentials of their products as an important innovation area.

Life cycle assessments are used to evaluate the environmental impact of a product throughout its life and consider the impact of the materials and processes used in the manufacture, distribution, use and final disposal. Using such an approach can allow designers to understand the impact that their choices may have on the environmental performance of the finished product, making appropriate selections early on in the development cycle.

In this presentation, it will be described how Domino has used life cycle assessments to identify innovation opportunities with their product lines, as well as how they are incorporating sustainability indicators into their development process.

Smart Coatings

Ander Cervellera Dominguez

Marie Curie Sklodowska Early Stage Researcher

AkzoNobel R&D, Sassenheim, The Netherlands / Department of Materials Science, The University of Manchester, UK

Materials that are capable of adapting their properties to an external stimulus are called responsive, or smart. The term “smart coating” refers to the concept of coatings being able to sense their environment and make an appropriate response to that stimulus.

Looking back, the standard thinking regarding coatings has been as a passive layer unresponsive to the environment. The current trend in coating technology, however, is to tune the coating composition with the idea of controlling the assembly of sequential macromolecular layers and the development of materials that can form defined structures with unique properties that can bring solutions to the current problems. To this purpose, smart coatings systems are being developed, examined, and are currently under investigation by numerous laboratories and industries.

In the aerospace industry for example, their is the need to replace toxic strontium chromate as the active corrosion inhibitor. My own work is part of the ongoing development of smart coatings as the promising technology for controlling the release rate of more soluble sustainable active corrosion inhibitors while providing long-term corrosion protection.

Sensing and sensed coatings

Raul Davalos-Monteiro

Marie Curie Sklodowska Early Stage Researcher

Corrosion & Protection Centre, School of Materials, The University of Manchester, Manchester, UK / AkzoNobel, Powder Coatngs, Como, Italy

A wide-ranging definition describe a sensor as a device, module, or machine, whose purpose is to detect events or changes in its environment and respond the information to frequently a computer processor where is normally quantified. The specific inputs for sensing could be any one of a great number of environmental phenomena, like light, motion, heat, current, pressure. Etc. In the world of organic coatings sensing has a vast number of applications, passing from all the industrial phases from formulation, testing and production.

My work focuses on the development cycle of new protective organic coatings, where a substantial amount of time is dedicated to perform corrosion testing, in order to ensure adequate field performance. Reducing the time related with corrosion testing would significantly reduce development time and decrease costs. Unavoidably, laboratory corrosion testing relies on some degree of acceleration of the, often unknown, failure mechanisms. Excessive acceleration of one degradation mechanism with respect to the others might result in poor or absent correlation between laboratory testing and field environment results. Thus, some of the most popular technological corrosion testing methods require long times.

Fundamental Study to Elucidate the Transport Mechanism of Leaching Corrosion Inhibitor from Primer Coating

Gh. R. Emad1, A. Cervellera-Dominguez1, Y. Liu1, S.B. Lyon1, S.R. Gibbon2, X. Zhou1

1 Corrosion and Protection Centre, Department of Materials, The University of Manchester, M13 9PL, UK

2 AkzoNobel, Stoneygate Lane, Felling, Gateshead, NE10 0JY, UK

Primer coatings pigmented with corrosion inhibitors are commonly used to protect metallic materials against corrosion. Effective inhibitors should leach to the defect regions with sufficient concentration to provide effective inhibition and should prevent excessive leaching to maintain the desired long-term release behaviour for the designed service life. However, the transport mechanism of leaching inhibitor within polymer coatings and the associated inhibition mechanisms of either chromate or non-chromate pigments are still not fully understood, consequently, the design of effective primers with environmentally friendly inhibitor pigments is still a tedious and costly process. In the present study, the leaching process of strontium aluminium polyphosphate from a polymer coating is monitored using time-lapse X-ray nanotomography and electron microscopy with X-ray energy dispersive spectroscopy (EDS).

A model polyester polymeric matrix incorporated with strontium aluminium polyphosphate hydrate (active inhibitor) was used in this study. Leaching measurements were performed to quantify the transport process as a function of the pigment volume concentration (PVC) through immersion testing in NaCl solution of different pH. Through the real time visualization of individual pigment particles and their 3D spatial connections in the polymer matrix, the transport route of the leaching inhibitor species in the polymer matrix has been explored. It is found that the strontium-rich component within the coating leaches extensively while the aluminium-rich component is more resistant to dissolution. The increase in PVC of the active inhibitor resulted in higher leaching rates of Sr and P, suggesting that coating microstructure, especially the connection of the inhibitor particles, has significant influence on the transport paths, specifically, the binder/pigment interface and the free volumes formed due to the dissolution of the pigment particles appear to serve as the main transport paths for the leaching of the inhibitive species. Further, the concentrations of strontium and phosphate species within the polymer matrix were below the detection limit of EDS, indicating that the diffusion of the inhibitive species through the polymeric binder is low. However, the higher dissolution rate of active inhibitors in acidic (pH=1.5) and alkaline (pH=12) environments and the destructive action of these conditions on the polymeric matrix appears to promote transport within the polymeric binder, implying that higher leaching rate is expected in the regions adjacent to the cathodic and anodic regions of a corroding metal substrate, which is beneficial to inhibition of localized corrosion.

Eugenio Bonetti

Marie Curie Sklodowska Early Stage Researcher

AkzoNobel Industrial Coatings AB, Malmö, Sweden / Department of Chemical Engineering and Analytical Science, The University of Manchester, UK

Formulating a coating is not just mixing ingredients. The choice of the components is a fundamental step and is determined by the properties that are required for a specific application. Due to the complexity of the formulations, changing one component often results in drastic changes of the performance and in the need to reformulate the coating. This, in turn, involves time-consuming experimental work to explore the formulation space and to test the performance, until the desired properties are obtained. As an example, the replacement of toxic chromate-based corrosion inhibitors in aerospace coatings with more soluble lithium carbonate alters the release rate of active species, thus affecting the protection properties of the new formulation.

In this perspective, modelling and simulation techniques can be useful tools to support the development of new improved coating formulations by providing a complementary approach to experimental work to identify and investigate the relationship between the composition of a coating and its observed properties. To this aim, my project focuses on developing a model of the relationship between the release of corrosion inhibitors from primer coatings and the microstructure of the coatings.

Control of Transport Through Coatings

Apoorva Ambarkar

Marie Curie Sklodowska Early Stage Researcher

AkzoNobel R&D, Sassenheim, The Netherlands / Department of Materials Science, The University of Manchester, UK

An ideal protective coating would act as a perfect barrier between substrate and environment, providing high resistant to movement of species through it. In reality, coatings are not perfect and fail to provide barrier protection over time. Often instead of preventing, they function by delaying the migration of species like ions, electrolyte, moisture, air etc through the coating. The transport of species causes the coating resistant to fall gradually and eventually coating failure. Thus, understanding and control of transport properties of coating allows us to develop better coating system and improve performance.

It is known that performance of an organic coating used for corrosion protection of metal is highly dependent on transport of moisture/water through it. Among other factors, intrinsic polymeric heterogeneity is believed to be an important factor for transport of water through a coating. A heterogenous coating can have susceptible areas that can lead to formation of percolating pathway for water and ionic ingress. My research work is focussed on exploring the structure-to-property relationship in BPANI packaging coatings for food-cans, where I am studying the influence of intrinsic polymeric heterogeneity on water uptake.

High aspect ratio barrier materials in coatings

Dr Noreen Thomas

Department of Materials, Loughborough University

An important success for both polymer/clay and polymer/graphene-based nanocomposites is the significant enhancement in moisture barrier properties that can be generated. In this presentation, results from the literature from both nano-clay and graphene-based systems will be compared to review what moisture barrier improvements can be achieved.

There are various models that predict the moisture barrier effects of planar fillers centred on a range of different factors: aspect ratio, concentration, platelet stacking, orientation, polymer chain confinement and plasticisation. The extent to which the predictive models are validated by experimental results is discussed, together with other considerations (such as processing route and pigment formulation) that can determine whether the potentially exceptional properties are realised.

Sustainable Coatings

Chi Him Lo

Marie Curie Sklodowska Early Stage Researcher

AkzoNobel R&D, Sassenheim, The Netherlands / Department of Materials Science, The University of Manchester, UK

Films and coatings can be found almost everywhere in our daily life; from packaging materials for food and pharmaceuticals, to digital printings and specialty films on durables and consumables, to architectural and industrial coatings on buildings and infrastructures. Manufacturers are becoming increasingly concerned about the issues of sustainability and taking proactive approaches to reduce their environmental impact. In the case of sustainable raw materials substitution, identification of replacements as well as development of quantitative methodologies to evaluate the economic and environment advantages are essential.

For the paints and coatings industry, the gradual transition from solvent-based to water-based paints has been a focus area in recent years. However, formulating water-based paints for long term corrosion protection comes with a unique set of challenges. My presentation will provide some insight into our work investigating the formulation aspects in the development of waterborne anticorrosive coatings.

Novel approaches towards faster corrosion testing

Raul Davalos-Monteiro

Marie Curie Sklodowska Early Stage Researcher

AkzoNobel Powder Coatings, Como, Italy / Department of Materials Science, The University of Manchester, UK

During the development or the modification of corrosion protection systems, a significant amount of resources are spent for corrosion testing, in order to ensure adequate lifetime in service. Some candidate systems might fail and be discarded after a relatively long test time; thus, the rapid identification of the systems that are likely to fail could potentially improve significantly the efficiency of the entire product development cycle.

Corrosion testing can be approached from a more technological or a more academic perspective. The technological approaches generally rely on well-standardized methods, such as salt spray testing, cyclic testing, UV exposure etc., whereby specimens are exposed to an aggressive environment for a set time and then evaluated. These methods have the advantage of well-defined pass or fail criteria, simplicity and high throughput, but suffer from the relatively arbitrary selection of the aggressive environment and produce little data that enable understanding of failure mechanism and inform re-design when needed.

On the other hand, more academic approaches rely on specific measurements to quantitatively assess the progress of the degradation during a particular exposure condition. This is often achieved by electrochemical measurements, which can provide quantitative information on degradation processes and on the presence or absence of specific degradation mechanisms. However, these methods are relatively complex, less standardized, and require an in-depth understanding of the systems and of the degradation processes.

This work presents recent approaches aiming to bridge the gap between the two methodologies, highlighting the commonalities and differences in degradation behaviours during salt spray, cyclic testing, immersion and various levels of electrochemical polarization. Further, the possibility of measuring electrochemically the advancement of degradation processes during technological testing has been inspected. In principle, the use of such hybrid methodologies has the potential of reducing significantly the time for corrosion testing, maintaining reliability and informing design.

Flexible Electronics for Printed Sensor Systems

Dr Simon Johnson

Cheif Technologist / Printable Electronics

Centre for Process Innovation, Newton Aycliffe, County Durham, UK

Electronic sensors require the measurement of parametric change, conditioning of the extracted signal and often conversion of the signal into digital form. In this presentation we will describe work at CPI in the printing of sensing devices and the integration of complete sensing system on flexible substrates. The assembly of rigid components onto flexible substrates presents challenges and we will describe processes that can be used to crate high volumes of product in continuous production processes. Such devices find application in healthcare devices and condition monitoring and examples will be given of these.

Printable Nanostructured Silicon for Temperature Sensing and other Applications

David Britton

PST Sensors Europe Ltd, NETPark, Thomas Wright Way, Sedgefield TS21 3FD

Over the last two decades the team behind PST Sensors have developed and refined nanostructured silicon materials for use in printed electronics. These materials have a surface stabilised by the presences oxygen, but do not build an insulating oxide layer in ambient or aqueous environments over years of storage or use. Although best known for its temperature sensitivity, and commercialised by PST in its printed NTC thermistor technology, nanostructured silicon has many unique properties not shared by its crystalline or amorphous equivalents. The temperature dependence of its electrical conductivity arises from thermally activated single-range hopping of charge carriers between nanostructured aggregates in a percolation network. This results in a low field effect mobility, comparable to amorphous silicon, and a very high single crystal-like Hall mobility, and a low effective free carrier density. Printed silicon sensors therefore have a high resistance, compared to conventional devices, making them ideal for ultra-low power applications in the IoT. The use of a printed structure further enables other parameters to be sensed in combination with temperature, and the electronic properties of the base material enable other electronics components such as transistors, varistors and diodes.

Life Cycle Assessment

Formerly: Dr Philip Taylor, Paints Research Associate, AkzoNobel Decorative Paints

Now: Phil Taylor, An ICI Pensioner

Phil Taylor is an ICI pensioner, who worked for AkzoNobel Decorative Paints (formerly ICI Paints) for thirty five and a half wonderful years. He worked in R&D studying formulation, synthesis and characterisation of polymers and paint, and qualitative and quantitative aspects of sustainability. He was also involved in Open Innovation for much of his working life. In this short talk, Phil will outline his experiences of qualitative and quantitative Life Cycle Assessment, drawing examples from Dulux paint.