Formulation 4.1

Putting Digital into Formulation

POSTERS

Links to:Morning Session, Poster Session, Afternoon Session

TOWARDS ‘FACTORY IN A BOX’ FOR PERSONALISED EMULSIONS ON DEMAND: HARNESSING VORTEX BASED HYDRODYNAMIC CAVITATION

Abhijeet H. Thaker and Vivek V. Ranade* Multiphase Reactors and Intensification Group, Bernal Institute, University of Limerick, Ireland

TOWARDS A HOLISTIC FRAMEWORK FOR COSMETIC FORMULATION 4.0

Jose Luis Rivera Gil1,2, Javier Andres Arrieta Escobar1, Juliana Serna Rodas1, Fatima Hamdani1, Paulo Narvaez, Vincent Boly2, Veronique Falk1.

1 Université de Lorraine, Nancy, France.

2 Universidad Nacional de Colombia, Bogotá, Colombia.

REAL-TIME DATA ANALYTICS/VISUALISATION OF BIG-DATA IN INDUSTRY 4.0

Zhicheng Lin, Payam Soulatiantork, Mohammad Zandi, Joan Cordiner and Peyman Z. Moghadam

University of Sheffield

INDUSTRIAL PRODUCT FORMULATION

Shyama Shiham, Apex Industrial Chemicals Limited, Aberdeen

TOWARDS ‘FACTORY IN A BOX’ FOR PERSONALISED EMULSIONS ON DEMAND: HARNESSING VORTEX BASED HYDRODYNAMIC CAVITATION - Poster

Abhijeet H. Thaker and Vivek V. Ranade* Multiphase Reactors and Intensification Group, Bernal Institute, University of Limerick, Ireland

Liquid-liquid emulsions for personalised products are gaining significant attention in many sectors for example; personal care (cosmetics, beauty care), home care (paints, room fresheners) and food (milk products, ice creams). Current bulk manufacturing technologies are slow in responding to changes, capital intensive, use unsustainable methods and not flexible to meet personalisation needs required for emulsions. Therefore, there is an urgent need to develop truly distributed manufacturing platforms. The present work takes first few steps towards developing such a ‘factory in a box’ platforms for producing emulsions with desired attributes. We use novel, vortex-based hydrodynamic cavitation devices1,2 for realising this. In this work, we present recent results on droplet breakage occurring in vortex-based hydrodynamic cavitation devices. The oil-in-water emulsion is prepared using 5% rapeseed oil in demineralised water. Tween 20 surfactant (2%) is used to prevent coalescence. The pressure drop in the device is maintained at 150 kPa. The inlet and final drop size distribution (DSD) is measured on-line using FBRM technique. To understand the complex multiphase flow field that develops in vortex-based cavitation device, transient CFD simulations are performed to simulate multiphase liquid-liquid-gas flows using Eulerian mixture model in Ansys Fluent R1. The phase change due to the cavitation is modelled using Singhal et al.3 cavitation model. The k−ω SST model is adopted for turbulence modelling. The effect of single and multiple passes on the emulsion DSD is investigated. The CFD results are used for quantitatively relating predicted pressure drop, velocity and energy dissipation rates required for the droplet breakage with the measurements. A single-pass was able to bring down droplet size from 200 μm to 10 μm. The measurements, models, devices, and strategies controlling droplet size distributions developed in the present work will pave the way towards realising next-generation ‘factory in a box’ platform for personalised emulsions.

Reference:

1. Ranade, V. V., Kulkarni, A. A., Bhandari, V. M. United States Patent. US9422952B2, (2016).

2. Sarvothaman, V. P., Simpson, A. T. & Ranade, V. V. Modelling of vortex based hydrodynamic cavitation reactors. Chem. Eng. J. 377, 119639 (2019).

3. Singhal, A. K., Athavale, M. M., Li, H. & Jiang, Y. Mathematical Basis and Validation of the Full Cavitation Model. J. Fluids Eng. 124, 617 (2002).

Q&A:

TOWARDS A HOLISTIC FRAMEWORK FOR COSMETIC FORMULATION 4.0 - Poster

Jose Luis Rivera Gil1,2, Javier Andres Arrieta Escobar1, Juliana Serna Rodas1, Fatima Hamdani1, Paulo Narvaez, Vincent Boly2, Veronique Falk1.

1 Université de Lorraine, Nancy, France.

2 Universidad Nacional de Colombia, Bogotá, Colombia.

Formulated consumer products design is a major challenge in many industrial sectors. Desired product properties depend on its application and usually are conferred by a synergistic action of ingredients, composition, and production process. From the search of various ingredients, to their combination in different proportions and process conditions, many solutions can be proposed. This large solution space should be reduced to satisfy the expectations of consumers, and the requirements from other stakeholders, notably those from the company where the product is designed. In this sense, all the business dimensions, must be in line with the product design project aspects such as the study of consumer needs and their translation, technical requirements, product conceptualization, selection of suppliers and raw materials, environmental objectives; marketing characteristics; quantitative sales and distribution goals. This multi-stakeholder and multi-objective process present a major problem for enterprises, as they must manage and process the knowledge and information throughout the formulation project.

In this work, a decision-making context is proposed based on the company business model for finding plausible formulations of cosmetic products. The framework uses a comprehensive fuzzy analysis of consumer preferences integrated into a mixed-integer optimization tool that incorporates available heuristic and property models. With this approach, teams involved in product design projects in cosmetic companies will be able to estimate the relevance and interactions of the consumer's subjective attributes and guide the design of innovative cosmetic products. In a further development, a similar approach should also be applied to the analysis of the other variables in the new product formulation process considering product sustainability, and supply chain analysis, to build a holistic framework for formulation. In this sense this research represents a contribution to Industry 4.0 in the cosmetic sector where the digitalization of product design, should be a major trend in a short term.

Q&A:

REAL-TIME DATA ANALYTICS/VISUALISATION OF BIG-DATA IN INDUSTRY 4.0 - Poster

Zhicheng Lin, Payam Soulatiantork, Mohammad Zandi, Joan Cordiner and Peyman Z. Moghadam

University of Sheffield

Keyword: data analytics; data visualization; smart manufacturing; real-time data analytics

Topic: Machine Learning and Big Data

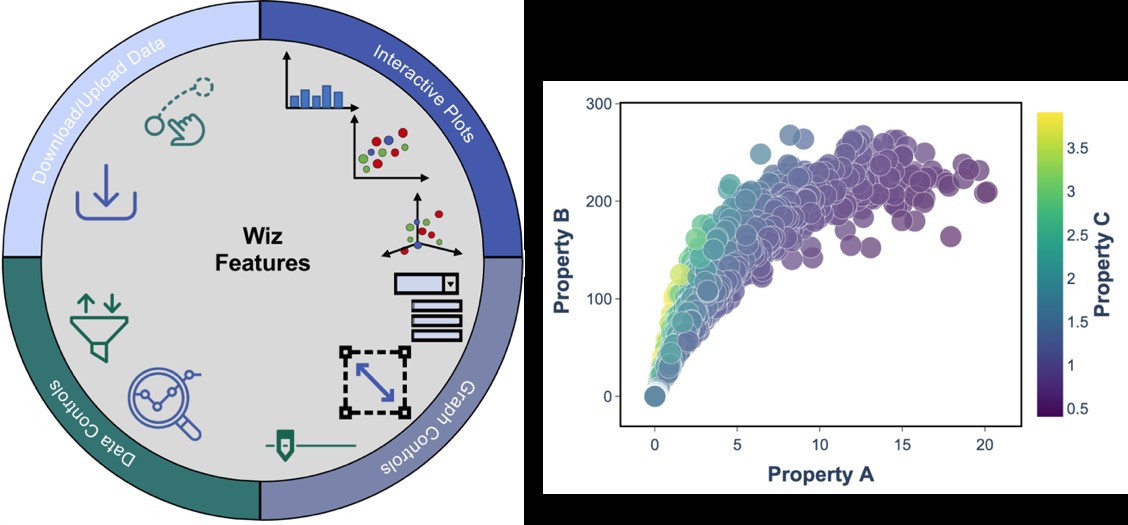

With the proliferation and exponential growth of data a fundamental need to interpret its content is created. Deciphering the insight within big data is crucial to maintaining a competitive advantage in the modern business environment known as industry 4.0. Here, we present Wiz, a web-based application for handling and visualising large amounts of data in real time (Fig.1). Wiz unravels the complexity of data by splitting their relationships through 5 dimensional (5D) visual analytics, identifies “bad data” and performs multivariate data analysis such as principal component and linear discriminant analyses, all in vivid interactive plots. Wiz is a one-stop-shop for Data Historian delivery that collect, analyse, and visualise information from a diversity of process equipment and business sources to enable real-time manufacturing intelligence solutions.

Fig. 1: Graphical overview of Wiz. Diagram of the main features of Wiz (left). These features work together to make the user experience of visualising and interacting with their data easier than ever. Prototypical 3D plot produced in the Wiz app (right).

Q&A:

INDUSTRIAL PRODUCT FORMULATION - poster

Shyama Shiham, Apex Industrial Chemicals Limited, Aberdeen

Performance testing in industrial formulation comprises mainly of trial and error - it is not always based on principles and theories. This is because each individual application method and substrate can differ, however a systemic approach towards the formulation makes a huge difference. This poster and presentation summarises five main criteria identified as critical for an industrial formulator. Years of formulation experience and knowledge has been collated in this presentation and may be useful in assisting the decision of any chemistry graduate who considers choosing the formulation sector as a career path. Each section is briefly discussed with key points and examples in the short presentation.

Q&A:

Links to:Morning Session, Poster Session, Afternoon Session

Abstracts must be submitted using the correct template and emailed directly to Dr. Helen Ryder at

Formulation 4.1

Putting Digital into Formulation

CALL FOR ABSTRACTS

Click here for guidelines for preparing your poster or check the bottom of this page.

Abstract submission for consideration for a Poster presentation is 23rd October 2020.

Abstracts must be submitted using the correct template and emailed directly to Dr. Helen Ryder at

No abstracts sent by other means (fax, post) will be accepted.

Instructions must be followed strictly and those not conforming to the required format will be disqualified.

The personal data of the presenting author must be filled in the submission form.

Abstracts should contain a sentence stating the study’s objective, a brief statement of methods, a summary of the results obtained and a statement of the conclusions. Please note that it will not be satisfactory to say ‘the results will be discussed’. Use a short and specific title. Capitalize initial letters of trade names. Abstracts must be written in English and can not exceed 300 words. Type your abstract using any word processor and using the template provided. Tables, graphics, figures and images can be included in the abstract. Ensure you include the title and authors in the abstract submission.

Topics

Industry 4.0 is a developing area and so we are keen to hear about a wide range of different ways in which science and technology are advanced formulation from design to consumption. Please ensure that your poster highlights the impact of Industry 4.0 on formulation and shows how your poster is either enabling Industry 4.0 or shows the impact of Industry 4.0 on business as usual.

Registration

All presenting authors must register for the meeting.

Acceptance

Once the abstract has been submitted, the presenting author will receive an e-mail message within 3 days as confirmation of receipt stating the submission reference number. Abstracts will be reviewed following the final submission date.

Cancellations

If you wish to withdraw or cancel your abstract submission then this must be done via email to Dr Helen Ryder by 2nd November 2020. Abstracts not withdrawn by 2nd November 2020 may appear in the program.

Organisers

Exhibitors

TBC